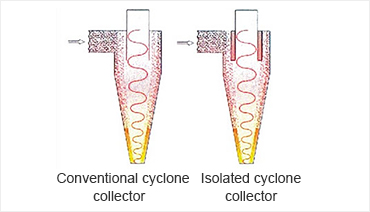

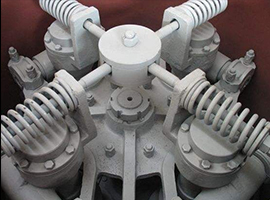

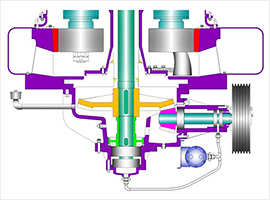

MTW Series Trapezoid Mill is Kefid in the absorption of European grinding technology and philosophy based on the development of patented products, with a number of independent patent rights, the model uses a bevel gear overall drive, internal thin oil lubrication system, curved duct and other new patented technology, as the traditional Raymond Mill, tilting mill replacement products, is widely used in power plant desulfurization, large non-metallic mineral milling and building materials and chemical and other fields.