Characteristics of Mine Breaking Industry

Advantage

Wide application range

Great development potential

large market demand

Inferiority

Large amount of investment

Complex project management

Limited geological conditions

Necessity of Configuring the Production Line

With the exhaustion of all kinds of mine resources, mining technology is transformed from primitive rough model to modern fine model. The effective mining and fine crushing will be done gradually. Therefore, in order to effectively process various ores and rapidly improve the ore's own value, the rational allocation of mining and crushing production lines is the top priority.

Production Line Composition

Medium crushingHST Cone Crusher

INPUT SIZE : 76-320MM

OUTPUT SIZE : 6-30mm

PRODUCTION CAPACITY : 55-700TPH

ADVANTAGE

-Adopts laminating crushing principle, ameliorate grain shape

-Efficiency improve by 5%- 15%, capacity increase by 35%-60%

-Intelligent control system, more accurate control, more stable

Applicable Material

Iron ore

Manganese ore

Gold ore

Bauxite

Copper ore

Tin ore

Case of Production Line

200TPH Granite Stationary Crushing Plant in Togo

MATERIAL : granite CAPACITY : 200t/h

MAX INPUT SIZE : 750mmLOCATION : Togo

FINAL PRODUCT SIZE: 0-4-6-10-14mm;

0-5-15-25mm; 0-31.5mm; 0-40mm

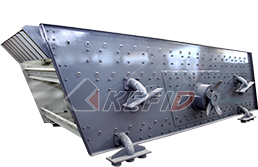

EQUIPMENT : LC4000X4000 hopper, ZSW 1300 x4900 vibrating feeder, PE900x1200 jaw crusher , LC4000X4000 surge hopper, HPT300/C hydraulic cone crusher, GZG110-4 vibrating feeder , and 4YZS2460 vibrating screen.

Kefid 150tph hard stone crushing line in Philippines

MATERIAL : hard stone, granite, basalt

FEEDING SIZE : 700mm

OUTPUT SIZE : 0-5mm-20mm-30mm

CAPACITY : approximate 150tph

EQUIPMENT : vibrating feeder ZSW1100x4200, primary jaw crusher PE750x1060, secondary cone crusher standard CSB160, vibrating screen 3YZS2160.

300-400tph Iron Ore Stone Crushing Line In Chile

MATERIAL : Iron Ore

MAXIMUM FEEDING SIZE : 750mm

FINAL PRODUCTS SIZE : 0-6mm

CAPACITY : 300-400tph

EQUIPMENT LIST : Jaw crusher PE900x1200, Cone crusher CSB240, 4 sets VSI5X sand making machine, Vibrating screen 3YZS2160, de-ironing separator.

Saudi Arabia 120-150 TPH Limestone Crushing Plant

MATERIAL : limestone

FEEDING SIZE : 630 mm

OUTPUT SIZE : 0-5-10-19mm

CAPACITY : 120-150 tph

EQUIPMENT : PE750 x 1060 jaw crusher + PF1315 jaw crusher

50TPH river stone crushing plant in Uganda

RAW MATERIAL : river stone

OUTPUT SIZE : 0-5-10-20mm

CAPACITY (TPH) : 50

APPLICATION PLAC : Uganda

EQUIPMENT:ZSW850x3000+PE500x750+2xPEX250x1000+3YZS2160

100-120 TPH Portable Limestone Crushing Plant in chile

MATERIAL : Limestone

FEEDING SIZE : 500 mm

OUTPUT SIZE : 0-6mm, 5-14mm, 14-25mm

LOCATION : Chile

CAPACITY : 100-120TPH