Home>Solution > dolomite processing line

Dolomite is a carbonate mineral composed of calcium magnesium carbonate CaMg(CO3)2. The term is also used to describe the sedimentary carbonate rock dolostone.Dolostone or dolomite rock is composed predominantly of the mineral dolomite with a stoichiometric ratio of 50% or greater content of magnesium replacing calcium, often as a result of diagenesis. Limestone that is partially replaced by dolomite is referred to as dolomitic limestone.

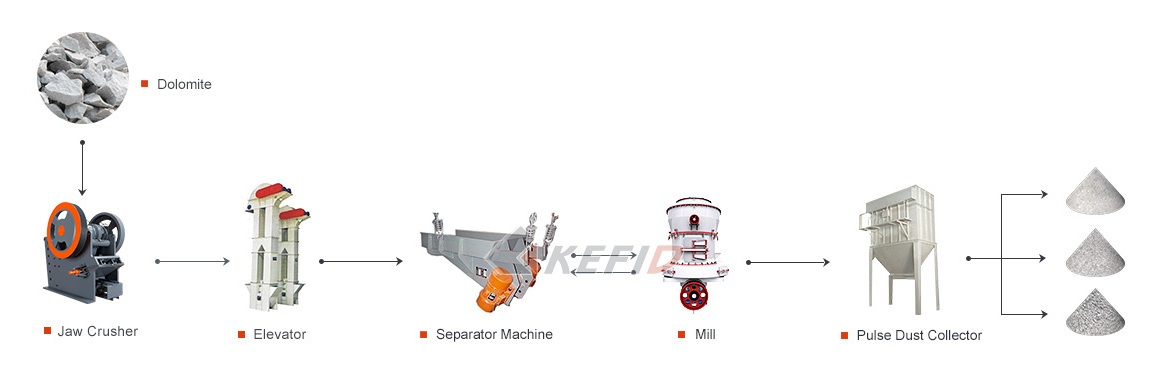

Bulk dolomite material is first crushed by jaw crusher into small particles and by the elevator sent into the storage bin.

Dolomite materials under the action of centrifugal force scattered around the circle, and fall into the grinding ring raceway inner ring rollers to shock, roll rolling, grinding, after a three-ring road into a powder processing, high pressure air through the suction effect of the external air sucked into the machine, and the crushed material powder sent to a separator machine.

In the separator machine, the rotating impeller makes the crude material down back into the mill machine for regrinding, and the other parts powder which are meet the requirements will with the air into the cyclone powder collector, and finally by its lower exhaust discharge valve to get the final product, a small amount of air with fine dust after through the purification of pulse dust collector and exhaust by muffler and fan.

MATERIAL: dolomite

CAPACITY: 8T/H

MATERIAL: dolomite

CAPACITY: 10T/H