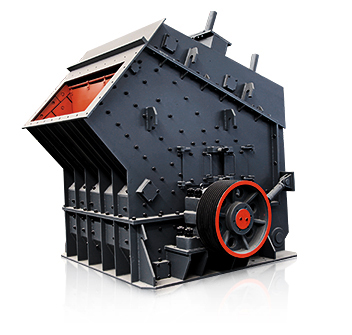

Impact Crusher

OUTPUT SIZE : Depends on the material PRODUCTION CAPACITY : 50-350TPH

APPLICATIONS : Railway road construcion other industries.

Chat online Leave a message- INTRODUCTION

- FEATURES

- TECHNICAL SPECIFICATIONS

By absorbing advanced technology in the world and combining experience in sand and gravel mining industry Kefid PF Series Impact Crusher uses the latest manufacturing technology and unique structure design; the final sizes share the advantages of cubic shapes no tension and no cracks. It’s suitable to crush various coarse medium and small materials (granite limestone concrete etc.) with the feeding size less than 500mm compressive strength less than 350MPa which has been widely used in ore crushing railway highway energy cement chemicals construction and other industries it can crush various ores and rocks such as: limestone cooked material slag coke and coal. The discharge opening can be adjusted under various specifications. Compared with hammer crusher PF series impact crusher offers larger crushing ratio and more fully utilizes the high-speed impact energy of the rotor which is the best choice in stone and gravel crushing line. However as crusher boards are easy to wear there is a limitation to crush hard materials PF series impact crusher is usually used for coarse and fine crushing of medium-hardness materials such as limestone coal calcium carbide quartz dolomite sulfide iron ore gypsum and chemical raw materials. The ideal feed size of PF impact crusher is 100-500mm the maximum sizes shall not exceed the specification.

According to the requirement users can adjust final particle sizes via the space between the hammer head and impacting plate.

- INTRODUCTION

-

By absorbing advanced technology in the world and combining experience in sand and gravel mining industry Kefid PF Series Impact Crusher uses the latest manufacturing technology and unique structure design; the final sizes share the advantages of cubic shapes no tension and no cracks. It’s suitable to crush various coarse medium and small materials (granite limestone concrete etc.) with the feeding size less than 500mm compressive strength less than 350MPa which has been widely used in ore crushing railway highway energy cement chemicals construction and other industries it can crush various ores and rocks such as: limestone cooked material slag coke and coal. The discharge opening can be adjusted under various specifications. Compared with hammer crusher PF series impact crusher offers larger crushing ratio and more fully utilizes the high-speed impact energy of the rotor which is the best choice in stone and gravel crushing line. However as crusher boards are easy to wear there is a limitation to crush hard materials PF series impact crusher is usually used for coarse and fine crushing of medium-hardness materials such as limestone coal calcium carbide quartz dolomite sulfide iron ore gypsum and chemical raw materials. The ideal feed size of PF impact crusher is 100-500mm the maximum sizes shall not exceed the specification.

According to the requirement users can adjust final particle sizes via the space between the hammer head and impacting plate. - FEATURES

1. Larger input size higher crushing cavity can process harder material with less powder in final products;

2. Easy adjustment of space between the impact plate and hammer effective control of the final sizes with good cubic shapes;

3. Compact structure good rigidity the rotor offers larger inertia;

4. High chrome hammer offers larger impacting force with less abrasion on easy-wearing parts;

5. New type rotor increases impacting force;

6. Full breaking function higher crushing ratio and productivity with lower energy consumption.

7. By using simple structure of expansion connection it’s easy to get maintenance.

Impact Crusher consists of main fr

ame rotor transmission device and impact plates. When the impact crusher works the motor drives the rotor with blow bars on it rotates at a high speed. When the material falls from a high point and goes into the area where the blow bar effects under the impact force it gets high speed and large dynamic energy. Then the materials are rebounded from the area where the blow bars to impact liner for recrushing then the materials are thrown to the impact liner from the rotor continuously. All the material from large to small sizes will be crushed in the impact cavity. The process won’t stop until the final sizes meet the requirement.

- TECHNICAL SPECIFICATIONS

Model Size of rotor (mm) Feed opening

(mm)Max. feed

size (mm)Capacity (t/h) Power of

Motor (kW)Weight (t) PF1010 Φ1000×1050 400×1080 350 50-80 75 12.5 PF1210 Φ1250×1050 400×1080 350 70-130 110 16.5 PF1214 Φ1250×1400 400×1430 350 90-180 132 19 PF1315 Φ1320×1500 860×1520 500 120-250 200 24 PF1320 Φ1320×2000 860×2030 500 160-350 260 27 Note: Any change of Impact Crusher technical data shall not be advised additionally.