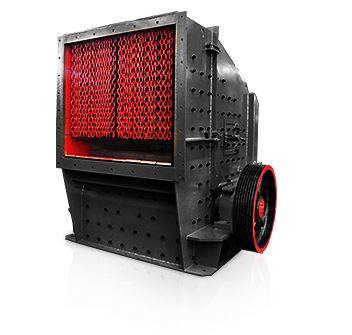

Primary Impact Crusher

OUTPUT SIZE : Depends on the material PRODUCTION CAPACITY : 90-400TPH

Applications :

By using international advanced technology Kefid PFP series primary impact crusher offers excellent quality and efficiency. Rotor as the heart of the primary impact crusher makes great contribution when working so it needs strict quality control. We developed stronger rotor to produce heavier moving inertia. Hard wear resistant material and the best cavity design make sure the excellent performance of the crusher which is suitable to crush various medium-hard and soft materials to coarse sizes. The PFP series impact crushers are mainly used in me

- INTRODUCTION

- FEATURES

- TECHNICAL SPECIFICATIONS

By using international advanced technology Kefid PFP series primary impact crusher offers excellent quality and efficiency. Rotor as the heart of the primary impact crusher makes great contribution when working so it needs strict quality control. We developed stronger rotor to produce heavier moving inertia. Hard wear resistant material and the best cavity design make sure the excellent performance of the crusher which is suitable to crush various medium-hard and soft materials to coarse sizes. The PFP series impact crushers are mainly used in me tallurgy mining cement chemicals refractory ceramics and other industrial sectors and have been widely used in the highway construction water conservancy projects building stone and other fields.

- INTRODUCTION

-

By using international advanced technology Kefid PFP series primary impact crusher offers excellent quality and efficiency. Rotor as the heart of the primary impact crusher makes great contribution when working so it needs strict quality control. We developed stronger rotor to produce heavier moving inertia. Hard wear resistant material and the best cavity design make sure the excellent performance of the crusher which is suitable to crush various medium-hard and soft materials to coarse sizes. The PFP series impact crushers are mainly used in me tallurgy mining cement chemicals refractory ceramics and other industrial sectors and have been widely used in the highway construction water conservancy projects building stone and other fields.

- FEATURES

1. Using world-class manufacturing process and good-quality raw material.

2. Heavy-duty design and rigorous tests to ensure the quality of the rotor.

3. Using integrated steel bearing structure.

4. The unique fixtures make the hammer more reliable.

5. Improved adjustment device reduces stop and maintenance time.

6. Choosing larger-size bearing with higher carrying capacity.

7. Analysis of the rotor ensures stability and reliability.- TECHNICAL SPECIFICATIONS

P model Spec. Feeding

size (mm)Max. feeding

size (mm)Capacity (t/h) Power (kW) Weight (t) PFP 1210 Ф1150X960 1100X1030 400 90-160 90-110 17.0 PFP 1214 Ф1150X1400 1100X1430 500 130-200 132-160 22.0 PFP 1315 Ф1300X1500 1200X1530 600 180-320 160-200 29.0 PFP 1318 Ф1300X1800 1200X1830 700 240-400 200-250 34.0 If there is change of the above specification it subjects to the newest products' specifications.

Note: Any change of Primary Impact Crusher technical data shall not be advised additionally.