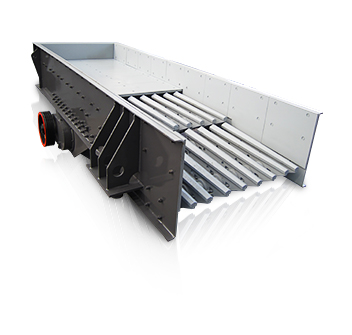

TSW series vibrating Feeder

OUTPUT SIZE : Not more than 800 mm PRODUCTION CAPACITY : 80-850T/H

APPLICATIONS : TSW series vibrating feeder is widely used in crushing and screening devices in the industries of me

- INTRODUCTION

- FEATURES

- TECHNICAL SPECIFICATIONS

TSW series vibrating feeder summarizing the design production sales and service experience in the mining industry for many years TSW series vibrating feeder is our company’s new efficient feeder which combines with the development of modern industrial technology extensively absorbs foreign advanced technology and independent research and development and design.

- INTRODUCTION

-

TSW series vibrating feeder summarizing the design production sales and service experience in the mining industry for many years TSW series vibrating feeder is our company’s new efficient feeder which combines with the development of modern industrial technology extensively absorbs foreign advanced technology and independent research and development and design.

- FEATURES

1.Big feeding ability high efficiency

The TSW series vibrating feeder all adopts the 4-pole motor which can enhance the rotary speed of the eccentric shaft immensely; The 2-stage grid bars and the installation angle highly promote the feeding ability and the working efficiency; With larger size and higher capacity TSW series vibrating feeder can meet the requirements of efficient and intensive industrial production.

2. Adjustment control is convenient and accurate

TSW series feeder adopts Y series motor and frequency conversion controller which is easy to adjust and more accurate in speed adjustment.

3. High reliability with enhanced supporting device design

Side plate and rear supporting board of the feeder adopt 16Mn steel plate; bottom plate and side guard plate adopt NM360 steel plate which has high strength. It improves the body wear and deduces the maintenance. The bar adopts ZGMn13-4 steel plate which has stronger structure bearing and lengthens the life.

4. stable operation easy maintenance

TSW feeder has simple and compact structure small size light weight motor undercarriage fixed to the foundation does not participate in vibration increasing the reliability of equipment operation.- TECHNICAL SPECIFICATIONS

Form 1: TSW series vibrating feeder technical specification

Model Max. feeding

size(mm)Capacity (t/h) Rotation speed

(rpm)Groove size (mm) Weight(kg) Dimension (mm) TSW0936 500 130-280 750-900 960×3600 3.95 3680×2136×1953 TSW1139 600 150-350 750-900 1100×3900 4.32 3980×2276×1953 TSW1345 700 250-450 750-900 1300×4500 4.97 4580×2570×1980 TSW1548 850 350-650 750-900 1500×4800 6.57 4880×2832×2044 TSW1852 1000 450-850 740-860 1800×5200 7.43 5280×3145×2059 TSW2156 1150 650-1000 700-850 2100×5600 9.86 5680X3520X2359

Form 2: Accessory parameterModel V-belt Motor VFD

(KW)Feeder driven

wheel diameter

(mm)Motor wheel

diameter (mm)Model Qty. Model Power

(KW)TSW0936 SPC2800 3 Y2-160L-4 15 15 Φ420 Φ244.6 TSW1139 SPC2800 3 Y2-160L-4 15 15 Φ420 Φ244.6 TSW1345 SPC2800 3 Y2-180L-4 22 22 Φ420 Φ244.6 TSW1548 SPC2800 4 Y2-200L-4 30 30 Φ530 Φ290 TSW1852 SPC2800 4 Y2-225S-4 37 37 Φ570 Φ290 TSW2156 SPC2800 5 Y2-225M-4 45 45 Φ600 Φ290 Note: The feeder’s capacity may influence by many factors: material physical and mechanical properties material shape feeding method and etc.The feeder’s capability is ba

sed on the stone with middle hardness whose bulk density is 1.6t/m³.