Kenya 20t/h dolomite grinding mills

- Material : Dolomite

- Feeding Size : 100mm

- Output Size : 0.074mm

- Capacity : 20 tons / hour

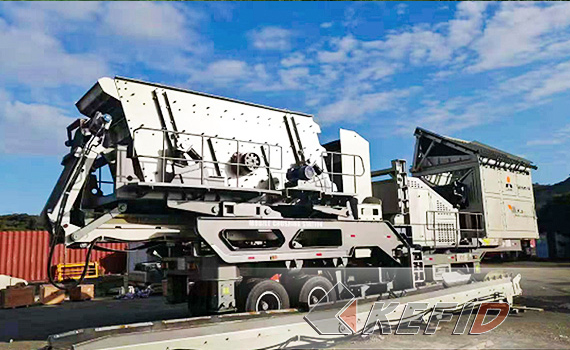

- Configuration : jaw crusher + bucket elevator + vibrating feeder + MTW175 European Tech. grinding mill

- CRUSHING PROCESS

-

Bulk dolomite material is first crushed by jaw crusher into small particles and by the elevator sent into the storage bin.

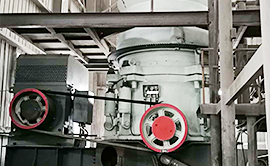

Dolomite materials under the action of centrifugal force scattered around the circle, and fall into the grinding ring raceway inner ring rollers to shock, roll rolling, grinding, after a three-ring road into a powder processing, high pressure air through the suction effect of the external air sucked into the machine, and the crushed material powder sent to a separator machine.

In the separator machine, the rotating impeller makes the crude material down back into the mill machine for regrinding, and the other parts powder which are meet the requirements will with the air into the cyclone powder collector, and finally by its lower exhaust discharge valve to get the final product, a small amount of air with fine dust after through the purification of pulse dust collector and exhaust by muffler and fan - Customer feedback

- The customer visited our factory and domestic customer site. He is very satisfied on the mill system and is also convincing us of technical support, thus excluding the other manufacturers, finally choosing Kefid. After operation,the mill successfully achieve the customer's requirements.

- Necessary Equipment

- Related Case