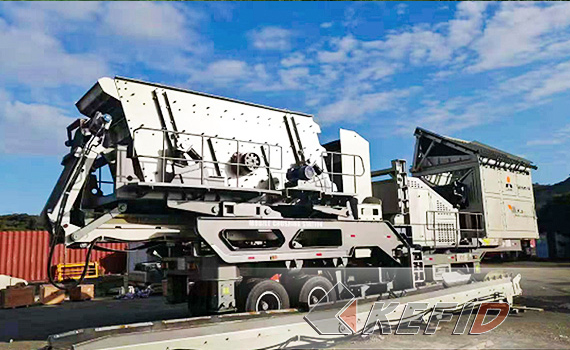

50TPH river stone crushing plant in Uganda

- Raw material : river stone

- Output size : 0-5-10-20mm

- Capacity (TPH) : 50

- Application plac : Uganda

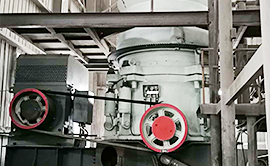

- Equipment : ZSW850x3000+PE500x750+2xPEX250x1000+3YZS2160

- CRUSHING PROCESS

-

1. Hopper. The hopper can be made in your local working site under the guidance of our engineer, since it takes too much place during shipping, waste of money.

2. The materials in the hopper will be fed into the jaw crusher PE500x750 by vibrating feeder ZSW850x3000 continuously and crushed to below 120 mm. At the same time, the raw material with size smaller than your required size will be screened out from the grate bar of the feeder, conveyed together with the discharging products from jaw crusher PE500x750.

3. After crushed by jaw crusher PE500x750, the materials below 120 mm will be transported to screen, after screening, the bigger size than your required will be transported to two sets of jaw crusher PEX250x1000 for crushing, the products of required sizes will be screened out and divided to different size.

4. After crushed by PEX250x1000, the material will be transported to screen again. The bigger size will be transported to PEX250x1000 for crushing again, the required size will be screened out and divided to different sizes.

5.This crushing line is a close circle. Moreover, all crushers use one belt conveyor to transport material for saving land.

- CUSTOMER FEEDBACK

- Kefid of configuration of the broken line for us only coarse crushing jaw crusher and secondary crusher, and the whole production line is a circle, connect all crusher by a belt conveyor, on the basis of saving cost for us, also save the land, for we are very satisfied with the cooperation

- Necessary Equipment

- Related Case