Home>Solution > cement processing line

In the most general sense of the word, cement is a binder, a substance that sets and hardens independently, and can bind other materials together.

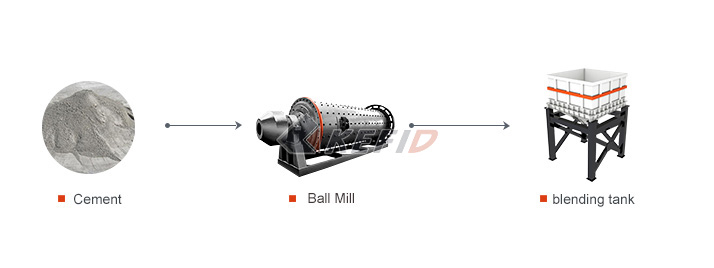

1. Cement's Wet Process: In the wet process, raw material should be proportioned to meet a desired chemical composition and fed to a rotating ball mill with water. The raw materials are ground to less than 75 microns. Materials exiting the mill are called "slurry" and have flow ability characteristics. This slurry is pumped to blending tanks and homogenized. Following the homogenization process, the slurry is stored in tanks until required.

2. Cement's Dry Process: In the dry process, raw material should be proportioned to meet a desired chemical composition and fed to either a rotating ball mill or vertical grinding mill. The raw materials are dried with waste process gases and ground to a size where the majority of the materials are less than 75 microns. The dry materials exiting either type of mill are called "kiln feed". The kiln feed is pneumatically blended to insure the chemical composition of the kiln feed is well homogenized and then stored in silos until required.

MATERIAL: limestone

OUTPUT SIZE: 0-5-10-19mm

MAX FEED SIZE: <630 mm

CAPACITY: 120-150 tph

MATERIAL: limestone

OUTPUT SIZE: 800 mesh

MAX FEED SIZE: 30mm

CAPACITY: 2.5 tons / hour