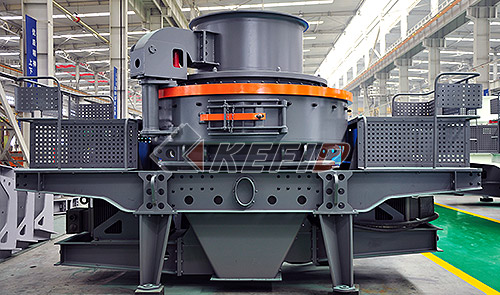

The stones for producing mechanism sand

Source: Kefid Shanghai Machinery Views: 1059

Mechanism sand refers to particles of different sizes of crushed rock sieved to less than 5 mm.

The commonly used production mechanism sand materials are limestone, granite, sandstone, quartzite, rhyolite, basalt, diorite, gneiss, diabase, tuff, pebbles, river pebbles, etc. The strength, mineral composition, rock structure and chemical composition of the rocks are different, which has an important influence on the energy consumption, stone powder content and grain shape of the mechanism sand crushing process. The expansion of the fracture is closely related to the internal structure of the rock and the characteristics of the rock.

1. Dense fine-grained limestone, which is mostly linear acicular rupture during crushing, and each crack rarely interacts, resulting in blasting fracture.

2. Marble and limestone minerals have similar properties, but the particles are larger, so large-scale macroscopic cracks are generated in the shear zone, and the plastic deformation of the calcite particles reduces the stress concentration at the toe end of the crack, so the crack propagation is hindered and rarely for blasting fracture.

3. Granite consists of three different components with an interface between the components. The fracture of granite is related to micropores and cracks in the rock mass. The crack is more harmful than the micropores, and it occurs mostly at the boundary of the rock particles, which is generally caused by internal stress and temperature changes. The mica in the granite acts as a buffer to reduce breakage during the crushing process.

4. The content of sandstone powder in the basalt mechanism sand is twice that of the quartz mechanism sand, and the energy consumption of the stone powder product is 10 times that of the same quality mechanism sand.

In addition to stone, stone chips, melon seeds, tailings and other raw materials can also be sanded, the material is very extensive, specifically according to your own needs.

More details and equipment quotation, please contact our 24hour online customer service.